The technology of our generator

The technology of our generator

STG has designed and built the first prototype of a power generator that converts mechanical energy into electrical energy, and it is more efficient than currently available models. This enhanced efficiency is achieved through patented free-motion pistons and a simple design without a flywheel.

The direct injection of diesel, biogas, or hydrogen into the engine, combined with adjustable dynamic compression, allows for even better performance compared to solutions using a turbocharger.

The STG power generator is composed of four combustion chambers connected through two independent rods that mount linear generators.

This straightforward arrangement avoids unnecessary conversion of motion (from linear to rotary), while allowing the two pairs of freely moving pistons to have synchronized opposing motion with programmable compression. The result is high power development with further reduction in vibrations and noise.

Complete technical documentation and construction CAD drawings are available upon request.

Below are some technical and comparative features extracted from the conclusions of the engineering study conducted by RME:

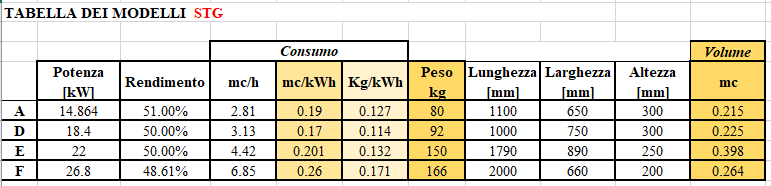

The STG power generator can be developed with various power outputs and sizes for different applications. Please refer to the table for details:

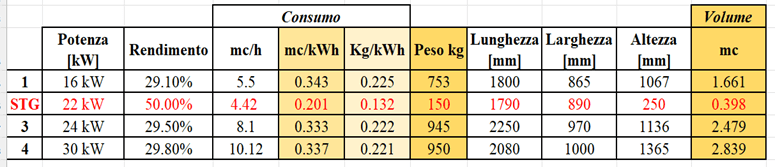

Comparison between linear generators, hereinafter referred to as linear generators, and traditional units currently on the market for: power, efficiency, consumption, weight, dimensions, and volume.

As evident from the data in the table, the STG generator achieves significantly better performance than current generators on the market, with advantages in terms of size, weight, and price as well. When comparing power and efficiency, the standout feature of the STG Linear Generator is its efficiency, which is over 50% higher than that of its competitors.

It’s worth noting that the efficiency of the STG generator is achieved with ETEL electric generators that are not yet optimized for electricity production. Therefore, with electric generators specifically designed for STG, the table would be even more skewed in favor of STG, making it a true revolution for generators of the future.

In terms of consumption, the STG Linear Generator is the best, offering the most advantages in terms of kg/kWh of electricity due to its lower consumption compared to the other three competitors. The consumption per cubic meter (mc) or kilogram (kg) per kWh of current for current generators is almost double that of the STG. However, it should be emphasized that the consumption of the STG is estimated conservatively at this project stage, and in practical terms, the difference could improve significantly.

In terms of weight, the STG generator is extremely lightweight.

In terms of volume, the space occupied by the STG generator is significantly smaller, allowing it to be installed in compact spaces.

In terms of dimensions, the height of the STG generator ranges from 20 to 30 cm, enabling its use in various sectors where other generators cannot be installed.

As indicated by AVL, an exclusive feature of this technology is its simple construction, consisting of only a few dozen components, with very few moving parts, in contrast to the hundreds of components, many of which are moving, that make up current generators on the market. Furthermore, the STG generator can be applied in situations where very low vibrations and noise are required.

CONCLUSIONS

The technical data obtained so far already demonstrate the immense potential of the STG generator in various models and in comparison with current generators on the market. The second prototype under construction will reaffirm the validity of this innovative technology, which is far superior to the current state of the art.

The data obtained through calculations, based on further development of the capabilities of linear generators, are truly remarkable. Simulations reveal that if we had linear generators with the ability to impart greater braking force to the magnets (similar to what current linear motors can achieve when operating at peak currents), we would have ultra-compact linear generators with much higher power and efficiency, two to three times greater than the current specifications.

Our generator, with its groundbreaking innovation, will revolutionize the generator market for many years to come.